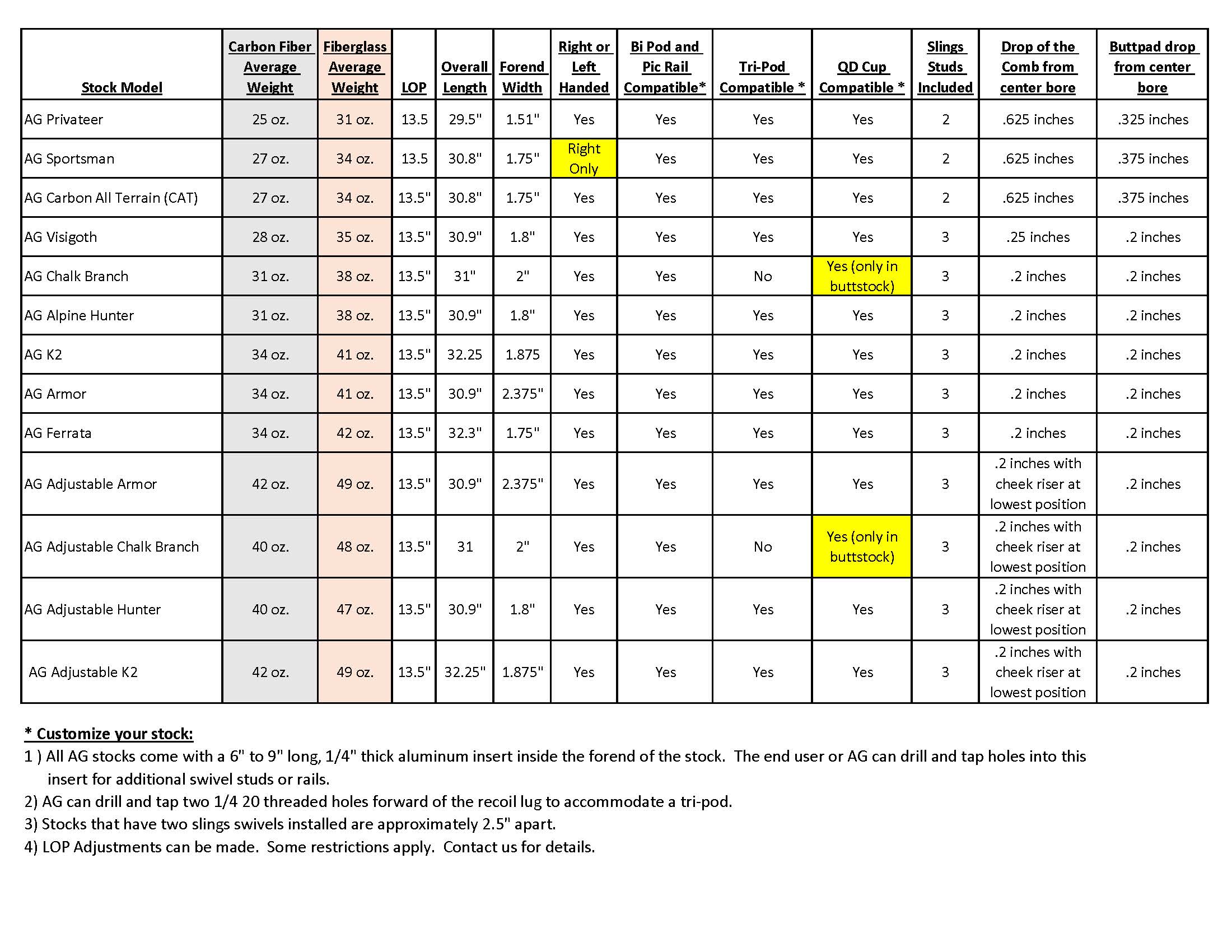

Technical Specifications

AG Composites LLC is a company with a passion for creating highly functional and reliable products that are designed and manufactured using state-of-the-art technologies and materials. Our unwavering commitment to customer satisfaction drives AG Composites' intense focus on innovation, quality, and performance.

It's our goal to deliver the highest quality composite rifle stocks available at competitive prices with lead times measured in weeks not months.

Design

AG Composites uses modern design software from Solidworks and AutoDesk to create Computer Aided Design (CAD) models of every stock we manufacture. AG Composites' design engineers bring their aerospace industry CAD modeling experience to every stock we design. CAD modeling has many advantages to include:

- Rapid exploration of many design concepts

- Precise modeling of stock inletting and compatibility with popular barrel contours, actions, and bottom metal

- Modeling of mold tooling and machining fixtures

Once AG Composites has a stock design that meets our criteria, the CAD model of the stock serves as the basis for all of the mold tooling and fixtures that are used to manufacture the stock. All AG Composite molds are precision CNC machined from metal to ensure that every one of the thousands of stocks that are produced out of a mold is an accurate reproduction of the original CAD model.

Materials

AG Composites uses the highest quality carbon fiber, epoxy, and paint products to manufacture our premium line of composite rifle stocks.

Carbon fiber is used extensively in industries where high performance is a necessity. From modern fighter aircraft to Tour de France winning bicycles to massive wind turbine blades, the incredible strength and amazing light weight of carbon fiber makes it the high performance go-to material. When designed properly, carbon fiber composite parts can offer the strength of steel but at a fraction of the weight.

All AG Composite stocks are made from carefully selected composite materials that have been extensively tested. Our stocks not only offer excellent stiffness and light weight, they are also impervious to environmental factors and will offer predictable, reliable performance for decades.

Manufacturing and Quality Control

AG Composites' proprietary manufacturing process is the secret sauce behind our ability to produce best-in-class stocks with delivery times that are a fraction of our competitors'.

Consistency, efficiency, cost control, and frequent quality control checks are the primary drivers of each step of our manufacturing process. Automation is used wherever possible starting with the high-precision cutting table that we use to cut every piece of carbon fiber material that is used in AG Composite stocks.

Computer controlled curing ovens guarantee that every AG Composites stock is fully cured and will not warp or crack at elevated temperatures such as those present in the cab of a pickup truck in the summer. AG Composite stocks are also compatible with hydrographic dipping and paint processes that use elevated temperatures.

All AG Composites stocks are CNC inletted to ensure a precise, drop-in ready fit with your action, bottom metal, and barrel. Also, all AG Composites can be bedded to tease out that last bit of accuracy.

Every AG Composites stock is test fit with action, bottom metal, and barrel hardware before it ships. It is time consuming and drives our quality control guy nuts but that is what it takes to get the job done right!

Looking Forward

AG Composites is not the type of company to sit back and think we have it all figured out. We are constantly looking at new technologies and materials in our endless pursuit to produce products that offer outstanding value and excellent performance for our customers. We are incorporating cutting edge manufacturing such as 3D printing while continuing to research the latest advancements in materials. AG Composites is proud to be a premier manufacturer of composite rifle stocks and we look forward to what the future holds!

CAD Drawings

Forend Shapes

Barrel Channels

Color Options

Manufacturing Videos

AG Composites Carbon Fiber Cutting Table

AG Composites BOOM

Carbon Fiber stocks getting blown up

AG Composites Carbon Fiber M1A stock (Durability Test)